A brief history of M 100 by Vincenzo Pedrielli

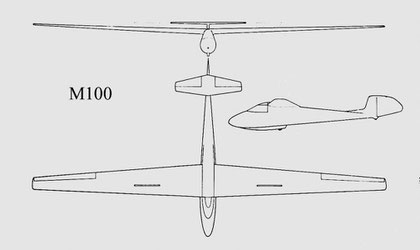

M-100

In January 1956 the Italian Aero-Club, in order to increase the number of sailplanes for the Italian gliding clubs, announced a competition among all Italian sailplane designers and manufacturers to select a modern single seat glider. According to the announcement of the competition, the sailplane should have been first of all low cost, strong and easy to repair and inspect, with characteristics for both sport activities and training for the achievement of C pilot licence. The quotation was requested for a single prototype and for a series of ten sailplanes.

On 14th April 1956 Alberto and Piero Morelli sent their proposal enclosing the drawing of a sailplane named M-100. That proposal was well accepted by the Aero Club who placed immediately the order for the prototype which was built by the company Nicolotti & Figli, specialised in wood work.

To keep the cost down the Morellis thought to limit the size of the sailplane, but fixing as a target an efficiency of 30 and a wing loading of 20 Kg/ m2.

As the wing load varies with the wing span and the aspect ratio, they choosed a wing span of 14 metres which resulted in a low weight and so in a low cost.

The fuselage cross section was designed following the experience of the Veltro with the reclined seat even if not as much as in the Veltro.

The tail plane was also designed based on the experience of the Veltro to reduce the damages in case of out landing, but the rudder surface was increased passing over the elevator to provide a great aerodynamic compensation surface.

The M-100 was built under the supervision of the members of CVT in only six month as committed in the terms of contract, but actually the time was not enough to thoroughly fix the performance of the sailplane.

When the M-100 was finished it was sent to the airfield in Rieti, where the test pilot Quirino Scano performed several tests which revealed a number of problems which were fixed by Alberto Morelli during all 1957.

The most significant improvements were applied to:

-To the ailerons which were modified from the usual hinged type to a slotted type to improve their efficiency at small deflections

-To the rudder by eliminating the part exceeding the elevator to reduce the excessive aerodynamic compensation.

-To the spoilers which were replaced by two pairs of counter-rotating plates made by fibre glass and polyester resin to prevent suction at the high speed.

Besides these changes, the control cables were replaced by push-pull rods. and the solid rubber landing wheel was replaced by a pneumatic one.

The modified rudder

M-100S

One year after the publication of the Aero Club competition, when the M-100 was almost completed, the FAI, throught their “Commission International de Vol sans Moteur”, introduced the Standard Class and released the specification based on the OSTIV proposal such as:

· Wing span not exceeding 15 meter

· Flap not acceptable

· Fix undercarriage with 300 mm wheel

· No radio on board

· Powerful airbrakes

The Standard Class was expected to take part to the World Championship in 1958 at Leszno in Poland, so the Italian Aero Club requested that the M-100 to be mass produced should have been modified to meet the Standard Class specifications. Under these circumstances the M-100S (with “S” standing for Standard) was designed with 15 meter wing span and the wing root section thickened from 14% to 18%.

The airbrakes were increased from two to three pairs of counter-rotating plates and they were very successful, allowing to land in a very short space, which is a very important feature in case of out landing.

Also the tail plane was completely redesigned. As a result the M-100S became a completely different sailplane.

The first prototype was built in Trento by the company Aeromere and tested with great satisfaction by Alberto Morelli on the Aeritalia airport on 23rd January 1960. The second prototype was made ready on 14th May of the same year and tested by

Captain Ferruccio Vignoli, experienced test pilot, who performed the severe FAI airbrake test. The M-100S, registered I-VELB, was brought to a safe altitude and dived with the air brake open not exceeding the speed of 200 Km/hour for 1600 meter (FAI requested only 1000 meter). At the question why he dived for 1600 meter instead of the prescribed 1000 meter, Captain Vignoli answered:

” I wanted to have a good margin for the result of the test!”

Production began at Aeromere and Avionautica Rio so a total of 83 sailplanes were produced in Italy. Later, the M-100S was produced in France by the company CARMAM of Moulins, which changed the name in Mésange and produced over 120 units in ten years over.

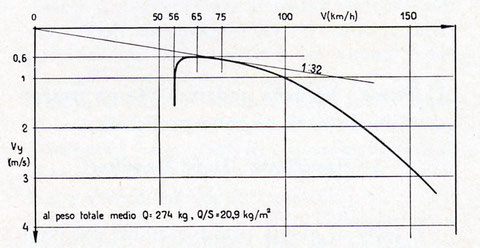

M 100 S Polar

Morelli M100S

Morelli M100S